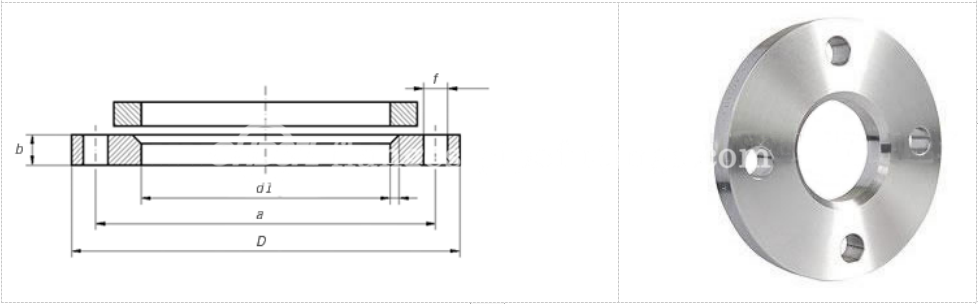

DIN 2642 PN10 SAUKI FLANGE

LAPPED FLANGE

Girman Flange & Kimanin Talakawa

| Jamus misali flange DIN 2642 lapped flange;matsa lamba 10 | |||||||||||

| Lose Flansche Vorschweißbördel Glatte Bunde DIN 2642 Nenndruck 10 | |||||||||||

| Brides Tournantes: pression nominale 10 | |||||||||||

| Bututu | Flange | Sukurori | Nauyi | ||||||||

| An ƙididdige shi | d1 | D | d6 | b | k | e | Ramuka | Zare | d2 | Kg | |

| ISO | DIN | ||||||||||

| 15 | - | 20 | 95 | 22 | 14 | 65 | 3 | 4 | M 12 | 14 | 0,689 |

| 21,3 | - | 24 | |||||||||

| 20 | - | 25 | 105 | 28 | 14 | 75 | 3 | 4 | M 12 | 14 | 0,806 |

| 26,9 | - | 30 | |||||||||

| 25 | - | 30 | 115 | 33 | 16 | 85 | 4 | 4 | M 12 | 14 | 1,11 |

| 33,7 | - | 36 | |||||||||

| 32 | - | 38 | 140 | 42 | 16 | 100 | 4 | 4 | M 16 | 18 | 1,64 |

| 42,4 | - | 46 | |||||||||

| 40 | - | 44,5 | 150 | 50 | 16 | 110 | 4 | 4 | M 16 | 18 | 1,86 |

| 48,3 | - | 54 | |||||||||

| 50 | - | 57 | 165 | 62 | 16 | 125 | 5 | 4 | M 16 | 18 | 2,20 |

| 60,3 | - | 65 | |||||||||

| 65 | 76,1 | - | 185 | 81 | 16 | 145 | 5 | 4 | M 16 | 18 | 2,62 |

| 80 | 88,9 | - | 200 | 94 | 18 | 160 | 5 | 8 | M 16 | 18 | 3,32 |

| 100 | - | 108 | 220 | 113 | 18 | 180 | 5 | 8 | M 16 | 18 | 3,67 |

| 114,3 | - | 119 | |||||||||

| 125 | - | 133 | 250 | 138 | 18 | 210 | 5 | 8 | M 16 | 18 | 4,54 |

| 139,7 | - | 145 | |||||||||

| 150 | - | 159 | 285 | 164 | 18 | 240 | 5 | 8 | M 20 | 22 | 5,60 |

| 168,3 | - | 173 | |||||||||

| 200 | 219,1 | - | 340 | 225 | 20 | 295 | 5 | 8 | M 20 | 22 | 7,46 |

| 250 | - | 267 | 395 | 273 | 22 | 350 | 5 | 12 | M 20 | 22 | 10,30 |

| 273 | - | 279 | |||||||||

| 300 | 323,9 | - | 445 | 329 | 26 | 400 | 5 | 12 | M 20 | 22 | 14.00 |

| 350 | 355,6 | - | 505 | 362 | 28 | 460 | 6 | 16 | M 20 | 22 | 18,50 |

| - | 368 | 374 | |||||||||

| 400 | 406,4 | - | 565 | 413 | 32 | 515 | 6 | 16 | M 24 | 26 | 25.00 |

| - | 419 | 426 | |||||||||

| (450) | 457 | - | 615 | 467 | 38 | 565 | 6 | 20 | M 24 | 26 | 30,60 |

| 500 | 508 | - | 670 | 517 | 38 | 620 | 6 | 20 | M 24 | 26 | 37.00 |

| 600 | 610 | - | 780 | 618 | 44 | 725 | 7 | 20 | M 27 | 30 | 56,30 |

| 700 | 711 | - | 895 | 721 | 50 | 840 | 7 | 24 | M 27 | 30 | 80,40 |

| 800 | 813 | - | 1015 | 824 | 56 | 950 | 7 | 24 | M 30 | 33 | 113,20 |

NOTE:

1. Fuskanci bisa ga DIN 2526

Tabbataccen fuska:

Form A, Fuska ba tare da wani buƙatu ba

Form B, Face Rz=160, injina (ba mai santsi fiye da 40µm)

Fuskar da aka daga:

Form C, Face Rz=160, injina (ba mai santsi fiye da 40µm)

Form D, Face Rz=40, injina

Form E, Face Rz=16, injina

2. Harshe da tsagi bisa ga DIN 2512

Form F, Harshe

Form N, Groove

3. Namiji da Namiji bisa ga DIN 2513, DIN 2514

Form V13, V14, Namiji

Form R13, R16, Mace

4. Chemfering na diaphragm-weld packings, PN64-PN400, bisa ga DIN 2695

5. Fuskantar haɗin gwiwa mai siffar ruwan tabarau, PN64-PN400, bisa ga DIN 2696

Ƙarfin samarwa & Cikakkun Sayi

1. Samar da Flange Dimension DN15 – DN2000 (1/2″ – 80″), Flange Forged.

2. Kayan Karfe Carbon: RST37.2, C22.8, S235JR, ST37, P235GH, P245GH, P250GH, ASTM A105

3. Kayan Bakin Karfe: ASTM A182 F304, F304L, F316, F316L, F321 da dai sauransu.

4. Flanges Anti Tsatsa: Anti Tsatsa mai, Black Paint, Yellow Paint shafa, Hot tsoma galvanized, Cold galvanized da dai sauransu.

5. Fitowar wata-wata: ton 3000 a kowane wata.

6. Sharuɗɗan Bayarwa: CIF, CFR, FOB, EXW.

7. Sharuɗɗan Biyan kuɗi: Canja wurin Waya (T / T), L / C da ba a iya canzawa ba a gani da sauransu.

8. Mafi ƙarancin oda: 1Ton ko 100Pcs.

9. Garanti mai inganci: EN10204 3.1 Takaddun Takaddun shaida, Takaddun Takaddun Mill, Binciken Na Uku, Sabis na Sauyawa Kyauta.

10. Nemo Ƙarin Bukatu A Kasuwar Flanges.